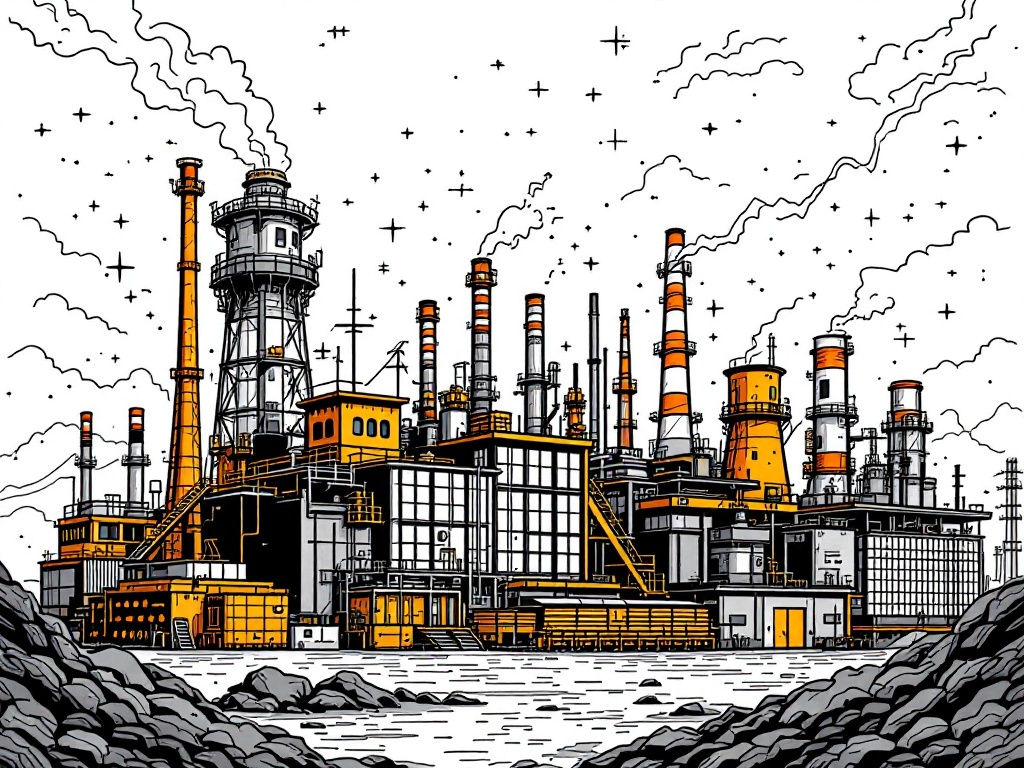

China's Ironmaking Innovation Increases Productivity 3,600-Fold

Beijing, Sunday, 8 December 2024.

Chinese researchers have developed a groundbreaking ironmaking method that completes the process in seconds, enhancing productivity, reducing costs, and significantly lowering carbon emissions in the steel industry.

Revolutionary Speed and Efficiency

The innovative flash ironmaking technology, developed by Professor Zhang Wenhai and his team at the Chinese Academy of Engineering, transforms the traditional ironmaking process by completing it in just 3 to 6 seconds, compared to the conventional 5 to 6 hours required by blast furnaces [1][2][3]. This remarkable achievement represents a 3600 times increase in productivity, marking a significant leap forward in steel manufacturing efficiency [1].

Technical Innovation and Production Capacity

At the heart of this breakthrough is a sophisticated vortex lance system that can inject 450 tonnes of iron ore particles per hour [1][3]. A reactor equipped with three such lances can achieve an annual production capacity of 7.11 million tonnes of iron [1]. The process involves injecting finely ground iron ore powder into an extremely hot furnace, triggering an explosive chemical reaction that produces high-purity iron suitable for immediate casting or one-step steelmaking [2].

Environmental and Economic Benefits

This groundbreaking technology promises to revolutionize China’s steel industry by improving energy efficiency by more than one-third [1][2]. Unlike traditional methods that heavily rely on coal and high-yield ores imported from Australia, Brazil, and Africa, this new process eliminates the need for coal entirely, enabling the steel industry to approach near-zero carbon dioxide emissions [2]. The technology, which has been refined since obtaining a patent in 2013 [1][3], works exceptionally well with low and medium-yield ores that are abundant in China [2].

Commercial Implementation and Future Prospects

The vortex lance has already entered commercial production [1], and with government statistics indicating an 80% success rate for pilot-tested technologies in China [1], the outlook is promising. While the concept of flash ironmaking originated in the United States, it was Zhang’s team that successfully adapted it for direct liquid iron production [1][3]. According to Professor Zhang, ‘The laboratory and pilot tests have confirmed the feasibility of this process’ [3], suggesting a bright future for this transformative technology in the global steel industry.