New Solar Reactor Transforms CO2 into Liquid Fuel, Signaling Shift in Circular Economy

London, Tuesday, 13 January 2026.

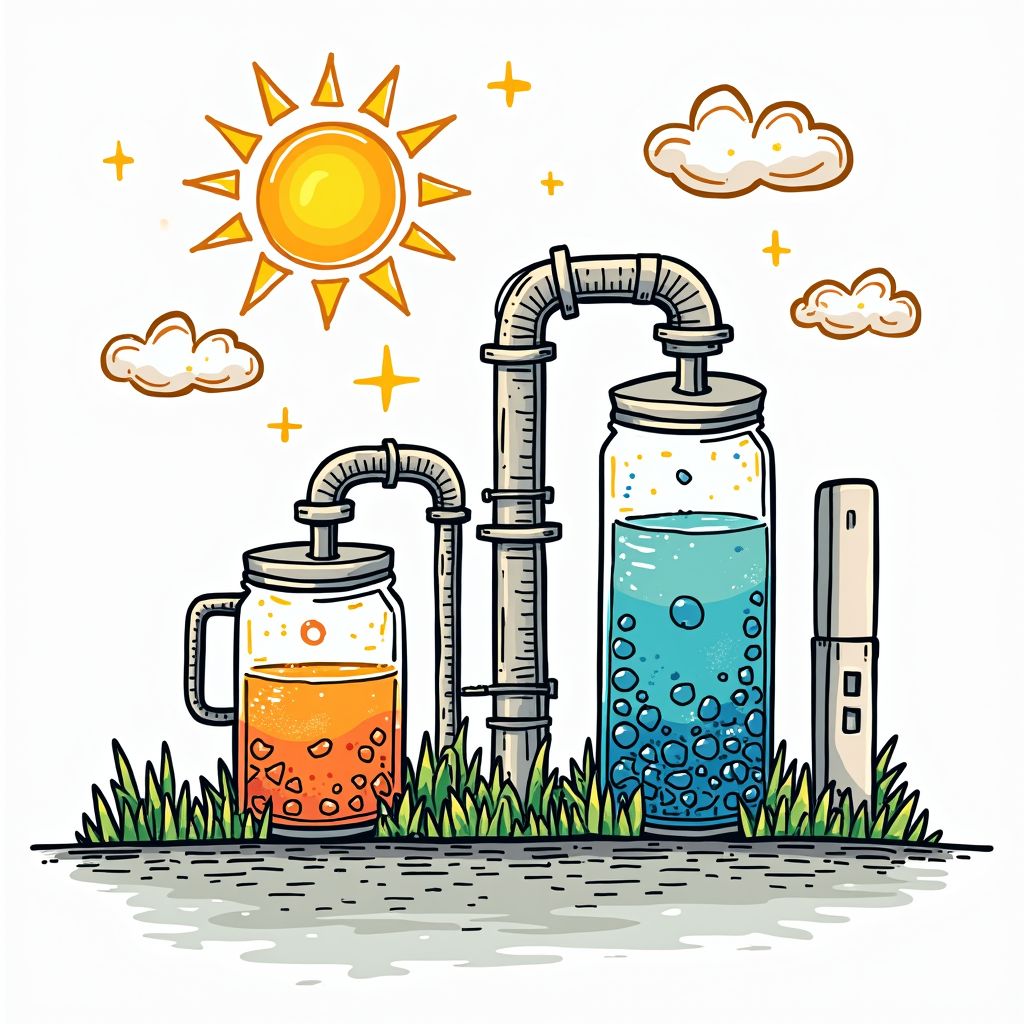

Researchers at the University of Cambridge have unveiled a solar reactor that converts CO2 and plastic waste into sustainable liquid fuels using only sunlight. By eliminating fossil-based electricity from the process, this breakthrough offers a scalable, decentralized pathway for the circular carbon economy, potentially redefining the viability of carbon capture and utilization for global energy markets.

Decoupling Fuel from Fossils

On Monday, January 12, 2026, a team at the University of Cambridge announced a significant advancement in chemical engineering: a reactor that synthesizes liquid fuels like diesel and methanol from carbon dioxide (CO2) and water using solar power [1]. Unlike conventional methods that rely on fossil-fuel-derived electricity to drive these reactions, this new system operates entirely on sunlight and captured carbon [1]. This development comes as the United Kingdom government commits £21.7 billion (approximately €25.3 billion) to Carbon Capture and Storage (CCS) infrastructure, highlighting a critical pivot from mere storage to active utilization in the energy sector [1].

The Economics of Solar-Integrated Production

For investors and policymakers, the integration of solar energy into chemical production fundamentally alters the cost structure of low-carbon fuels. A 2026 techno-economic assessment indicates that integrating solar power into post-combustion carbon capture plants can reduce energy penalties by 79% [2]. In the specific case of “blue hydrogen”—hydrogen produced from natural gas with carbon capture—solar integration creates a distinct price advantage. While conventional blue hydrogen costs approximately $2.01 per kilogram, optimizing the process with solar energy lowers the Levelized Cost of Hydrogen (LCOH) to $1.74 per kilogram [2].

Parallel Breakthroughs in Hydrogen

The push for decentralized, solar-driven fuel production is not limited to the UK. Researchers at Chalmers University of Technology in Sweden have simultaneously presented a method to produce hydrogen gas using sunlight and water without the use of platinum, a scarce and expensive metal typically required as a co-catalyst [3]. Published in the journal Advanced Materials, this new process utilizes tiny particles of electrically conductive plastic, or conjugated polymers, which have been modified at the molecular level to be more compatible with water [3][4].